Contact

Buildjob preparation for Laser Powder Bed Fusion in metallic materials

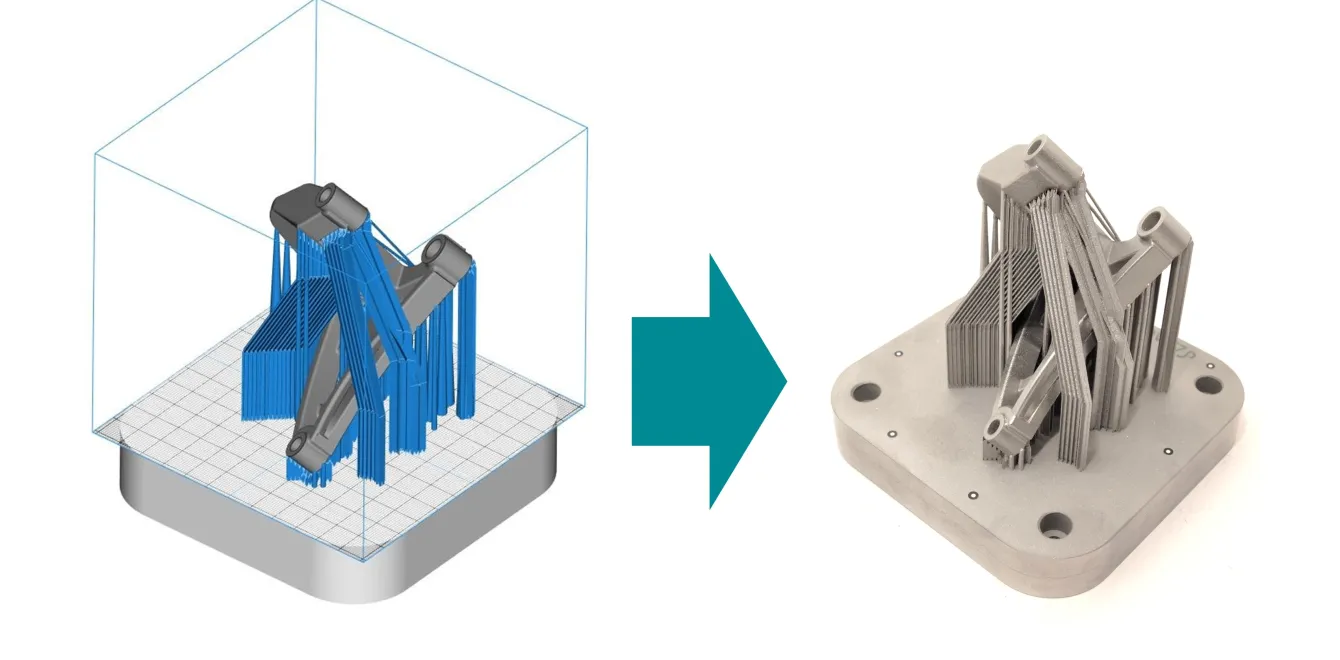

The initial step in manufacturing with Laser Powder Bed Fusion (L-PBF) is buildjob preparation, during which the process parameters, component and build strategy are defined and set. Connected with buildjob preparation an analysis of the preparation's manufacturability is carried out to estimate risks in the manufacturing process.

Purpose

RISE address the provided component geometry with respect to orientation in the build volume, support structure designs and assignment of process parameters. This generates a build file for the selected L-PBF machine.

There are several challenges associated with manufacturing components with L-PBF such as overheating, deformations, and more. These can cause problems during the process that lead to component failure during manufacturing or give an unusable result. Therefore, the preparation is combined with an analysis of these associated challenges to increase the probability for successful print.

RISE offers buildjob preparation for the metallic materials that have been approved by the machine supplier or RISE.

Method

The process consists of four steps that are performed in sequence but can advantageously be iterated to increase the manufacturability of the buildjob preparation.

The steps in the process

Component orientation - - based on customer specification in the form of written instructions / drawings or alternatively in the component file's coordinate system (z-direction indicates build direction). If there is no customer specification, RISE can offer recommendations based on parameters such as distortion tendency, cost and the need for support structure.

Support design - based on selected material, a suitable support structure is assigned and adapted based on process knowledge by our application engineers.

Assignment of process parameters - all approved materials have one or more parameter sets with different benefits. The selection is made in dialogue with the customer and assigned to the build file.

Analysis of manufacturability - can be carried out with great variation in scope. At the lowest level, the buildjob must be inspected by an application engineer to assess risk and be approved for the selected process. This process step can be extended with geometry analysis and process simulation according to costumer request.

Deliveries

The results are delivered according to agreement, but usually in the form of a written report together with the prepared buildjob file.

More information

This is one of many services included in the Application center for additive manufacturing. For more information visit: