Contact person

Substitution and risk management of thermosets and their additives

Thermosets are commonly used in the work environment and are used e.g. in adhesives and varnishes. In addition, many of the substances used are harmful to health. We offer help with finding replacements and also offer thermosetting plastic training according to the Swedish Work Environment Authority's regulation on Chemical work environment risks.

Thermosets are common in the work environment and are used in, for example, varnishes, adhesives and resins. Many of the substances used in the manufacture of thermosetting plastics are harmful to health. The same applies to thermosets that have not been completely cured, ie made hard, or that are heated. Some common thermosets are epoxy, acrylate and polyurethane. Polyurethane contains isocyanates that can be released during heating and grinding. Thermosets can cause, for example, allergies, asthma, eczema and be irritating to the eyes and mucous membranes.

Car repair shops, the construction industry, nail salons and dental clinics are examples of areas where thermosetting plastics are used frequently.

Training - work with thermosets

RISE can offer training in accordance with AFS 2014: 43 - "Work with thermosets", so that you and your company can handle and work with thermosets in a safe way. Our course material can be adapted for your particular business and based on the thermosetting plastic products you use.

We help you find replacements

We also work with finding, evaluating and verifying potential replacements for thermoset adhesives and solvent-based adhesives. We look at the whole process to reduce exposure through changed and /or automated processes.

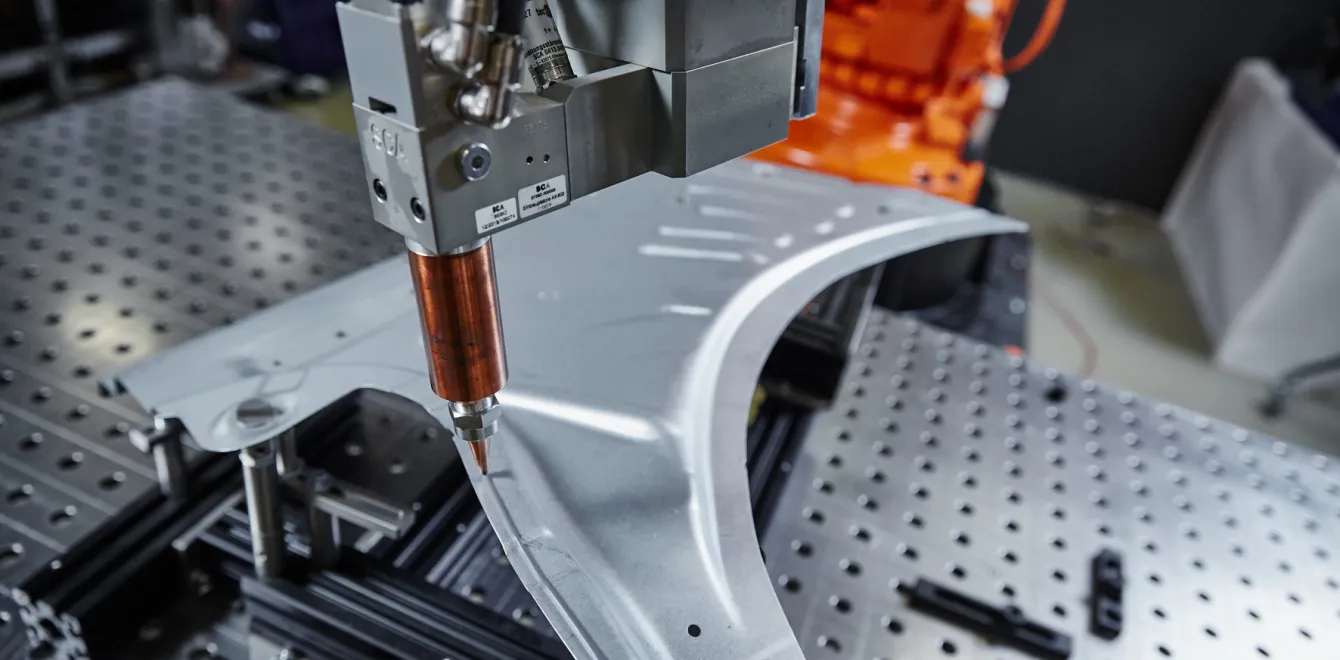

This may, for example, involve changing the properties of the joined surfaces by increasing their adhesion to the adhesive by, for example, plasma treatment, laser treatment, or by mechanical processing such as grinding. Likewise, the joined surfaces may need to be redesigned in their design to be able to be joined in another way, for example with mechanical joining. Simply, prevent exposure measures.

Evaluation and verification run in parallel. We can, e.g. work with and test this in our test beds; Paint center and HJT - Hybrid Joining Testbed. We always work from an environmental and work environment perspective.

Contact us for more information.

More information

Substitution means that you:

- Replace a hazardous substance with one that is less hazardous

- Switch to a different material

- Or find a completely new solution so that a hazardous substance is no longer needed, for example, by changing the design or process

Contact the Swedish Centre for Chemical Substitution for more information and guidance on phasing out hazardous chemicals in products and processes.