Contact person

Christina Wedin

Coordinator

Contact Christina

In order to develop and optimise the pulp process, it is important to test and characterise the pulp. This is partly to find out which properties are affected when the process conditions change.

Refining pulp for sheets and testing provides a good overview of the important properties of the end product for good quality. Evaluation of the fibre composition or the effect of meld chemistry is also possible. See RISE opportunities below. It is also possible to order mapping in use to monitor important parameters.

Refinery

Pulp properties

Preparation of the pulp

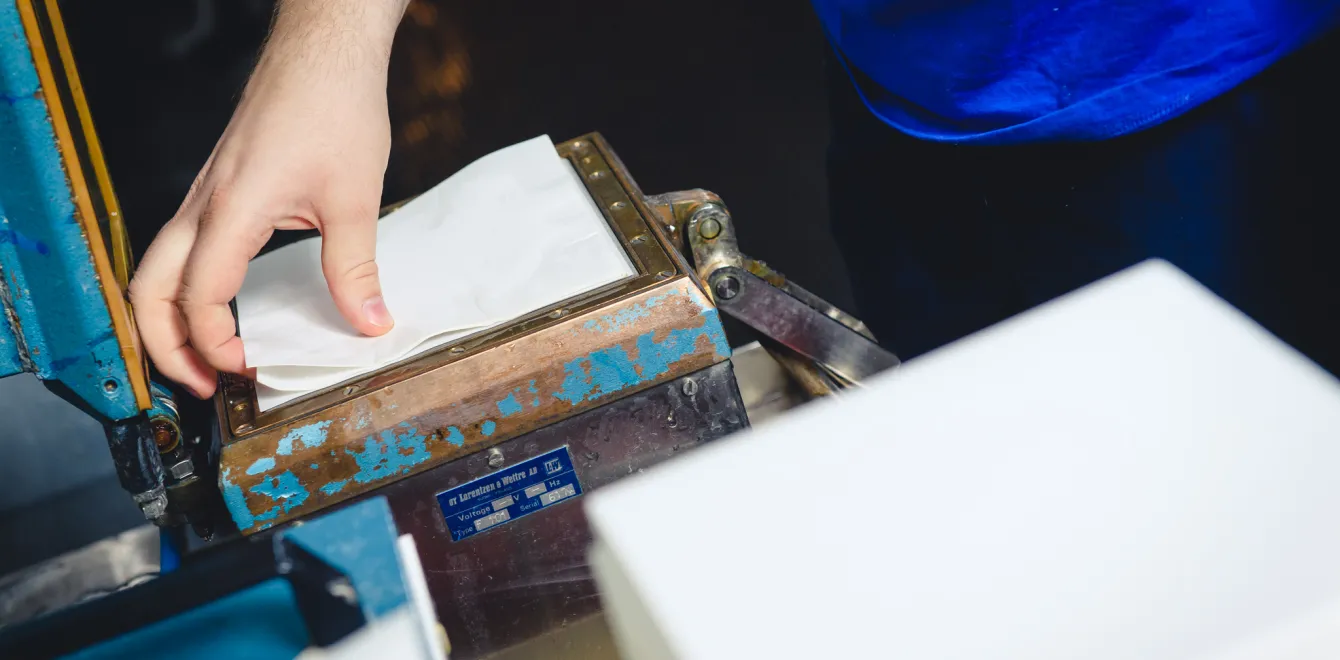

Laboratory sheet former

Properties of hand sheets

Optical properties

Fibre contribution

Bauer McNett, fibre fractions

Britt Jar, fines

Somerville, shives - screening of pulp stickies, plastics, sand, metal pieces, and flakes in recycled fibre.

Fibre dimensions

Impurities

Permanence

Meld chemistry

RISE delivers a report with data in Excel format, supplemented with relevant images and diagrams. The report is compiled according to standardised analysis methods and includes an assessment of measurement uncertainty as well as comments that deepen the understanding of the results. All relevant parameters for the current analysis are included.